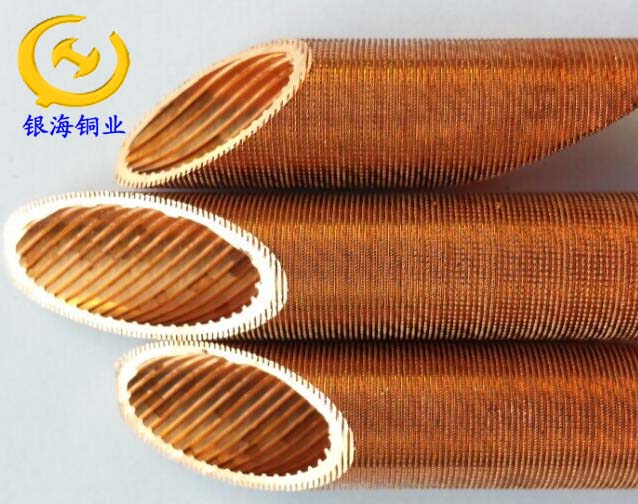

Strengthened condensing tube

Strengthened condensing tube is mainly used in centrifugal chillers, water chillers and shell and tube heat exchangers with small temperature difference. For outer surface condensation, the enhanced condensation tube improves the outer fin shape, making the outer fin spacing smaller and it has a sharp serrated notch. Therefore, compared with other tubes, it not only simply increases the heat transfer area outside the tube, but also divides the refrigerant into a very thin flow layer when it passes through. The friction between layers produces turbulent flow disturbance and changes the flow mode of the refrigerant, so it has a very high heat conduction efficiency. In addition, due to its special three-dimensional wing characteristics, the pressure loss can be significantly reduced when the refrigerant flows along the longitudinal direction of the tube. The inner surface of the tube can also be machined with spiral grooves to further improve the heat transfer area and turbulence action of the inner surface, and enhance the comprehensive heat transfer capacity. The volume and weight of the heat exchanger can be reduced correspondingly, and the energy saving and cost reduction can be achieved. This type of tube is also suitable for high viscosity refrigerant and is also effective in casing type heat exchangers.

Executive standards: GB/T19447 or equivalent to ASTM B359, ASME SB 359

Materials: red copper T2/TP2, iron white copper BFe10-1-1, complex brass Hsn70-1, HA177-2 etc.

Status: wing clip H02, smooth segment O60 or whole O60

Specifications:

Do: Φ12~Φ25.4mm

To: 1.0-1.5mm

Hf1: ≤1.0mm

FPI: 26-50 wing/inch

L: ≤5m

Packing: packed in wooden cases