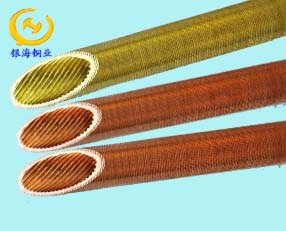

Enhanced evaporating tube

Enhanced evaporating tube is mainly used in centrifugal chillers, water chillers and shell and tube heat exchangers under small temperature difference.

Enhanced evaporating tube is a new type of heat exchange tube which can produce intense vaporization boiling on its outer surface. Its excellent heat conduction ability is the result of a unique pore structure, and the optimization design of micro pore structure is not simply to enhance the heat in area, and increased the evaporation vaporization core of large amount of heat required to change the evaporation of refrigerant flow way and helps to remove impurities and reduce the fouling, reduce tube outside heat resistance, significantly improves the thermal efficiency tube exchange; The inner surface of the tube is also processed with spiral groove, in order to further improve the inner surface of the heat transfer area and turbulence effect, reduce the heat resistance in the tube.

The improvement of the internal and external heat transfer efficiency greatly promotes the comprehensive heat transfer capacity of the tube, so that the volume and weight of the heat exchanger can be correspondingly reduced, to achieve the requirements of energy saving and cost reduction.

Executive standards: GB/T19447 or equivalent to ASTM B359, ASME SB 359

Materials: red copper T2/TP2, iron white copper BFe10-1-1, complex brass HSn70-1, HAl77-2 etc.

Status: Wing clip H02, smooth segment O60 or whole O60

Specifications:

Do: Φ15.88~Φ25.4mm

To: 1.0-1.5mm

Hf1: ≤1.70mm

FPI: 40-56 wing/inch

L: ≤5m

Packing: packed in wooden cases